T19001 Water Base Mud Solid Control System Scroll Discharge

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | LW |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD20000-140000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 70 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Discharge: | Scroll Discharge | Machine Control: | PLC Control |

|---|---|---|---|

| High Light: | T19001 Solids Control System,T19001 solids control equipment,Solids Control System Scroll Discharge |

||

Product Description

Complete PLC Control T19001 Solid Control System Scroll Discharge

Complete Solid Control System

![]()

Applications

- Well bottom cleaning

- Cutting carrying

- Cooling and lubrication of drill bit and drill string

- Control and balance of bottom pressure

- Cake forming to protect well walls

- Sand setting of suspended drill cuttings and weighting agent

![]()

Water-base Mud Solid Control System

Work System

Level-by-level removal of harmful solids is the working principle of Huada Centrifuge's solid control equipment system, which is roughly divided into four levels: shale shaker, desander, desilter and decanter centrifuge. The solid-phase separation is conducted according to the separation point of the equipment at corresponding level.

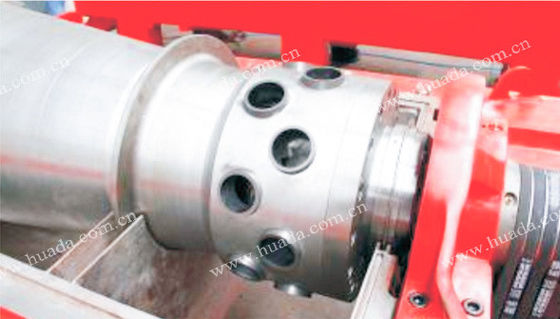

Complete Solid Control Device (Dedicated) - LW Decanter Centrifuge

LW drilling mud decanter centrifuge is designed to remove waste solids and fine particles in the drilling mud. It is applicable to the drilling mud containing a mixture of water and solids and traditional oil-based drilling mud.

![]()

Main Structural Features

- Vertical base design with symmetrically arranged motor and bowl, and smooth operation of the machine with low vibration level.

- Main parts and components such as bowl and scroll made of corrosion-resistant stainless steel or dual-phase steel, with high limit speed and large separation factor.

- Frequency conversion control, and steplessly adjustable speeds of both bowl and scroll.

- Pushing surface of the screw conveyor sprayed with wear-resistant alloy or inlaid with hard alloy.

- Three differential systems, i.e. cycloidal gearbox, planetary gearbox and hydraulic gearbox (Rotodiff), with a wide range of differential adjustment and strong adaptability to working conditions.

- Multiple safety protections: speed, differential speed detection, over-vibration protection, motor overload and overheating protection, bearing temperature monitoring, scroll conveyor torque protection, gas-tight explosion-proof deign, inert gas protection, etc.

- JG dedicated rubber shock absorber, fixing with anchor bolts not required.

![]()

![]()

Technical Parameters

| Items | Model | ||||||

| LW220*880 | LW355*1460 | LW450*1800 | LW530*2120 | LW650*2800 | LW720*2665 | LW1000*3000 | |

| Bowl Diameter (mm) | 220 | 350 | 450 | 530 | 650 | 720 | 1000 |

| L/D | 4 | 4.17 | 4 | 4 | 4.3 | 3.7 | 3 |

| Bowl Speed (r/min) | 4800 | 4000 | 3500 | 3200 | 2500 | 2000 | 1500 |

| Separation Factor | 2840 | 3132 | 3083 | 3035 | 2270 | 1600 | 1258 |

| Main motor power (kW) | 11 | 30 | 45 | 75 | 90 | 110 | 132 |

| Weight (kg) | 1000 | 2800 | 3600 | 4200 | 9600 | 12000 | 16000 |

| Dimension (L×W×H) | 2234*740*781 | 336*920*1060 | 4200*1090*1250 | 4885*1230*1350 | 5400*1750*1600 | 5365*3160*1510 | 5180*2450*1950 |

Complete Solid Control System - GZS Shale Shaker

The drilling fluid shale shaker is one of the main equipment of the solid control equipment. The effect of the shale shaker not only directly determines the working efficiency of solid control equipment at subsequent levels, but also affects the working conditions of the entire drilling engineering or HDD Engineering.

- Adopt ANANY limited element analysis to optimize structure

- Overall heat treatment of screen deck

- Heavy anti-corrosion coating on the surface.

- SS304 or Q345 high-strength alloy materials used.

- Italian OLI vibration motor selected.

Working Principle

The vibration exciter installed on the screen bed of the shale shaker produces an exciting force to make the screen bed vibrate. The screen bed applies force on the passing mud through the screen installed on it to separate the solids and liquids in the mud. The solid drill cuttings smaller than the screen mesh fall into the tank with the liquids, and the solid drill cuttings larger than the screen mesh and the adsorbed mud residue are transported out of the screen bed to the pool outside the tank.

Complete Solid Control System - LLL Vertical Cutting Dryer

Working Principle

The slurry enters the scroll inner chamber from the feed pipe and then enters the basket through the feed port at the top of the scroll. Under the action of the centrifugal force field, the liquid in the slurry is filtered out through the screen laid on the rotating wall, and the solid particles are trapped in the basket.

At the same time, the solid particles in the basket move from the top (small end) of the basket to the bottom (big end) of the basket under the action of centrifugal force and the relative differential speed between the spiral and the basket. During this movement, the centrifugal force is rapidly increased due to the increase in the rotation diameter, and the solids change from a high moisture content at the time of initial entry to the lowest moisture content at the time of discharge, realizing the automatic and continuous separation of solid and liquid phases.

![]()

Product Features

Optional basket cone angle according to the process conditions.

Independent lubrication system, simple and reliable lubrication method.

Special strip screen with good wear resistance and long service life.

Continuous feeding, separation, dewatering and unloading, with high treatment capacity.

3K planetary gearbox with compact structure and high driving torque.

Vertical layout of rotating parts such as the basket and scroll, good centering, stable operation and low vibration.