Drilling Mud Scroll Decanter Centrifuges

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | LW |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD20000-180000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 50 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Centrifugal Type: | Decanter Centrifuge |

|---|---|---|---|

| Discharge: | Scroll Discharge | Machine Control: | PLC Control |

| MOC: | Stainless Steel | Certificate: | ISO9001 |

| Operate: | Automatic Continuous Operation | ||

| Highlight: | Scroll Decanter Centrifuges,PLC control continuous centrifuge machine,GB Decanter Centrifuges |

||

Product Description

LW Model Continuous Drilling Mud Scroll Decanter Centrifuges

Description

LW series products are decanter centrifuges that can work continuously and are mainly used for solid-liquid separation, dehydration, fractionation, clarification, and concentration of materials. Based on different phase densities, it separates the solid phases and liquid phases under the action of the centrifugal force generated by the high-speed revolution of the Bowl. The solid phases are conveyed to the conical end of the Bowl through a spiral and then discharged, and the liquid phases are discharged out from the overflow port at the big end of the Bowl. Characterized by simple design, high efficiency and scientific configuration, this product has been widely applied to chemical, pharmaceutical, environmental protection, food, mining, energy and other industries.![]()

Driving Technology

Conjugate DC Bus Driving System

Dual-motor and dual-frequency driving mode is adopted for better differential regulation;

It is more adaptive to the change of working conditions to ensure the separation effect;

Dynamic feedback design is employed to reduce power consumption effectively.![]()

Advantages of LW Centrifuges

Structural Design

Large Length-to-Diameter Ratio (L/D) Design (≥4)

Increase the handling capacity

Extend the decanting duration and reduce the solid content in the clarified liquid to achieve 99% recovery of materials (maximum)

Optimized Spiral Design

Adopt the special vortex design

Reduce the impact on materials

Avoid the blockage of materials

Reduce the solid content in clarified liquid

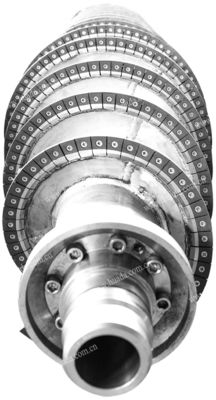

Special Screw Blade Design

Reduce the friction with materials

Reduce the material-pushing torque

Decrease the adherence of materials![]()

Centrifugal Casting Process Design

Centrifugal casting is adopted for manufacturing the Bowl and spiral shaft to improve the structural strength significantly

High-strength Self-cooling Bearing Seat Design

High structural strength

Good cooling effect

Advanced Anti-wear Technology

Advantages: wear resistance, prolonged service life and low maintenance cost.

Resistance to Clotting of Materials.

Axial wear-resistant steel is adopted for the Bowl, and replaceable wear-resistant sleeve (hard alloy or porcelain sleeve) is adopted for the feeding port and deslagging port.

Hot-sprayed hard alloy sheets, inlaid hard alloy sheets or high wear-resistant porcelain sheets are configured for screw blades![]()

LW Decanter Centrifuge (Standard Type)

Description

Labyrinth seal is adopted for both ends of the Bowl of the standard type of the LW series, which is simple yet efficient. After separation, the solid phases are pushed to the solid discharge outlet through a spiral and then discharged out of the Bowl under the action of the centrifugal force generated from high-speed revolution, and the clarified liquid is discharged out of the overflow port at the big end of the Bowl. Featuring simple operation, stable operation, high efficiency and high automation, and continuous working of 24 hours, this type is widely applied.![]()

Technical Parameters

| Model | Bowl Diameter (mm) | L/D | Bowl Speed (r/min) | Separation Factor | Power of Driving Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LW220*880 | 200 | 4 | 4800 | 2840 | 11 | 1000 | 2660*740*780 |

| LW300*1290 | 300 | 4.3 | 4400 | 3250 | 15 | 1500 | 3250*960*1000 |

| LW355*1460 | 350 | 4.17 | 4000 | 3130 | 22-30 | 2200 | 3550*1010*1030 |

| LW450*1800 | 450 | 4 | 2800-3200 | 1575-2580 | 30-37 | 3500 | 4150*1090*1250 |

| LW450*2050 | 450 | 4.5 | 3200-3600 | 2580-3265 | 30-37 | 4000 | 4350*1090*1250 |

| LW530*2120 | 530 | 4 | 2800-3200 | 2330-3040 | 45-55 | 5300 | 4850*1230*1450 |

| LW530*2650 | 530 | 5 | 2500 | 1850 | 55 | 6000 | 5400*1230*1450 |

| LW650*2800 | 650 | 4.3 | 2500 | 2270 | 90 | 9600 | 5400*1750*1600 |

| LW720*2880 | 720 | 4 | 2000 | 1610 | 110 | 11000 | 5300*2050*1750 |

| LW850*3200 | 720 | 3.76 | 2000 | 1900 | 160 | 16000 | 6750*2280*1900 |

| LW1000*3000 | 1000 | 3 | 1500 | 1260 | 132 | 16000 | 5200*2500*2000 |