Stainless Steel 904L Amino Acid Dewatering Centrifuge Horizontal Peeler Discharge

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB 19815-2000, GBT19001-2016/ISO9001:2015 |

| Model Number: | GK |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD25000-120000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 70 work days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Centrifugal Type: | Basket Centrifuge |

|---|---|---|---|

| Discharge: | Scraper Discharge | Operate: | Automatic Batch Operation |

| Machine Control: | PLC Control | Basket Length (mm): | 325-1000 |

| Centrifuge Name: | Peeler Centrifuge | Basket Diameter (mm): | 600-1800 |

| Highlight: | Amino Acid dewatering centrifuge,04L industrial centrifuge separator,dewatering centrifuge horizontal peeler |

||

Product Description

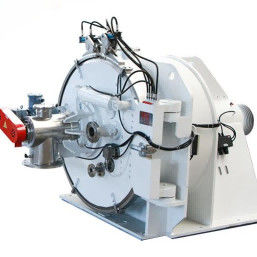

GK Horizontal Peeler Discharge Stainless Steel 904L Amino Acid Dewatering Centrifuge

Peeler centrifuge is continuously rotating and intermittently operation centrifuge. It can be either automatic control or manual control.

The whole process of operation including materials feeding, separating, cleaning, dewatering, discharging and filter cloth recycling can be achieved at full speed. Single cycle of processing materials is shortly but with large quantity. The solids cake can be well dried and cleaned.

Peeler centrifuge is widely used in such industries as chemical, food, light industry, pharmaceutical, etc. It is suitable for separating suspension containing large-size or medium-size or small-size particles, such as sulphuric ammonia, carbonic ammonia, PVC, etc.

Siphon peeler centrifuge is designed on the common peeler centrifuge basics. By the siphon to increase the force pushes the clarified liquid passing through the filtration medium into the liquid chamber. The liquid is drained out of the basket through the sucker. Adjusting the position of sucker could change the liquid level in the suction chamber to adjust the force of filtration, speed, output, dryness of the solid cake and effectiveness of cleaning.

Set a recoil fitting. Pour washing liquid into the suction chamber and the overflow chamber if it needs. Washing liquid flowing into the basket will resume the filtering performance of the filtration medium when it passes through it.

Product Dimension

| Items | GK600 | GK800 | GK1000 | GK1250 | |

| Chute/Floating Platform | Machine | 2500*1890*1300 | 2760*1980*1550 | 3400*2170*2020 | |

| Installation | 3400*2500*1900 | 3900*2500*2200 | 4600*3200*2600 | ||

| Chute/Steel Platform | Machine | 2400*1350*1400 | 2200*2100*1700 | 2460*2400*2100 | 3660*2100*2600 |

| Installation | 2800*1800*1400 | 2800*2100*1700 | 3300*2400*2100 | 4800*2900*2600 | |

| Floating Platform | 2600*2300*400 | 2630*2360*450 | 3100*2600*500 | ||

| Spiral Discharge/Floating Platform | Machine | 3800*2170*2020 | |||

| Installation | 4800*4000*2600 | ||||

| Items | GK1350 | GK1600 | GK1800 | |

| Chute/Floating Platform | Machine | 4000*2750*2480 | ||

| Installation | 5700*4100*3500 | |||

| Chute/Steel Platform | Machine | 4400*2100*2700 | ||

| Installation | 5400*3000*2700 | |||

| Floating Platform | 4040*3400*700 | 4700*3600*800 | ||

| Spiral Discharge/Floating Platform | Machine | 4850*2750*2480 | 5650*2850*2700 | |

| Installation | 6100*4700*3500 | 6500*5600*4000 | ||

Technical Parameters

| Items | Model | |||||||

| GK600 | GK800 | GK1000 | GK1250 | GK1350 | GK1600 | GK1800 | ||

| Basket Diameter (mm) | 600 | 800 | 1000 | 1250 | 1350 | 1600 | 1800 | |

| Basket Length (mm) | 325 | 450 | 500 | 600 | 680 | 800 | 1000 | |

| Filtering Area | 0.61 | 1.13 | 1.57 | 2.45 | 2.88 | 4 | 5.65 | |

| Basket Volume (L) | 45 | 100 | 165 | 355 | 465 | 700 | 1100 | |

| Max. Loading Weight (kg) | 60 | 135 | 220 | 460 | 600 | 930 | 1500 | |

| Basket Speed (r/min) | 2400 | 1550 | 1400 | 1200 | 1200 | 950 | 800 | |

| Separation Factor | 1935 | 1076 | 1098 | 1008 | 1088 | 808 | 645 | |

| Power of Driving Motor (kW) | 22 | 30 | 37 | 55 | 55 | 90 | 132 | |

| Weight (kg) | Chute | 3500 | 6000 | 8000 | 14000 | |||

| Chute+Steel Platform | 3500 | 6000 | 10000 | 13500 | 21000 | |||

| Floating Platform | 5000 | 6000 | 9000 | 21000 | 33000 | |||

| Spiral discharge | 8500 | 15000 | 23000 | |||||

![]()

This type has high performance in separating suspensions with the cake density of 0.8~2.5, particle size of 0.05mm~1mm and solid concentration of 15%~80%.

It has been widely applied in the chemical, food, pharmaceutical, light industry and other industries for separating such materials as sodium bicarbonate, caustic soda, starch, boric acid, ammonium sulfide, sulfuric acid, sodium sulfate, ferrous sulfate, calcium phosphate, polyvinyl chloride, sodium chloride, and potassium chloride.

![]()

![]()