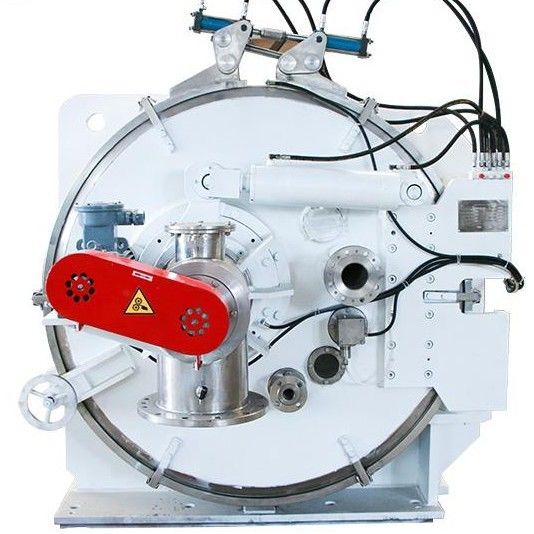

Automatic Flexible 600mm Peeler Centrifuges 22kW Agricultural Horizontal Centrifuge

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB 19815-2000, GBT19001-2016/ISO9001:2015 |

| Model Number: | GK600 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD20000-140000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 70 work days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Basket Diameter (mm): | 600 | Centrifugal Type: | Basket Centrifuge |

|---|---|---|---|

| Filtering Area: | 0.61 | Operate: | Automatic Batch Operation |

| Machine Control: | PLC Control | MOC: | Stainless Steel |

| Centrifuge Name: | Peeler Centrifuge | Power Of Driving Motor (kW): | 22 |

| Highlight: | Peeler Centrifuges 22kW,22kW horizontal centrifuge,600mm Peeler Centrifuges |

||

Product Description

GK Continuous Processing Automatic Flexible Peeler Agricultural Horizontal Centrifuge

GK horizontal centrifuge is a type of automatic filtration centrifuge featuring continuous running, intermittent operation and high-speed peeling, which is able to complete feeding, separation, washing, dehydration, discharging, back-blowing and other processes at full speed, and therefore is commonly applied to the washing and solid-liquid separation of suspension medium containing solid particles.

With high separation factor, short single circulation duration and large handling capacity, relatively dry residues after filtration can be obtained and ideal washing effect can be ensured.

![]()

This type has high performance in separating suspensions with the cake density of 0.8~2.5, particle size of 0.05mm~1mm and solid concentration of 15%~80%.

It has been widely applied in the chemical, food, pharmaceutical, light industry and other industries for separating such materials as sodium bicarbonate, caustic soda, starch, boric acid, ammonium sulfide, sulfuric acid, sodium sulfate, ferrous sulfate, calcium phosphate, polyvinyl chloride, sodium chloride, and potassium chloride.

![]()

Technical Parameters

| Items | Model | |

| GK600 | ||

| Basket Diameter (mm) | 600 | |

| Basket Length (mm) | 325 | |

| Filtering Area | 0.61 | |

| Basket Volume (L) | 45 | |

| Max. Loading Weight (kg) | 60 | |

| Basket Speed (r/min) | 2400 | |

| Separation Factor | 1935 | |

| Power of Driving Motor (kW) | 22 | |

| Weight (kg) | Chute | |

| Chute+Steel Platform | 3500 | |

| Floating Platform | ||

| Spiral discharge | ||

Product Configuration

• Control mode: PLC control, with touch panel and human-machine interface and supporting electric-hydraulic actuator to realize automatic remote control.

• Multiple safety protections: speed detection, overvibration protection, cover opening protection, overload protection, overtemperature protection, peeler action protection, nitrogen protection, electromagnetic interlocking, etc.

• Discharge mode: open discharging through chute or integrated discharging with peeler conveyed through spiral.

• Hydraulic coupler can be adopted for the transmission of models below GK1250 to realize stable startup, simple control and effective overload protection of motor.

• Variable-frequency control, dynamic braking or energy feedback braking, stepless regulation of speed are designed to realize energy saving, environmental protection and more reliable operation.

• Optional configurations: online washing system, nitrogen protection system, steel platform, hydraulic locking device, etc.

![]()

Operation process

Feeding

The material enters the rotating basket through the feeding pipe, and the cake layer controller controls n times of pulse feeding to fill the basket in limited manner. Usually, the material cake can reach 75-80% of the basket lip. Feeding is completed once the solid cake reaches the pre-set thickness.

Filtration Skimming-Filtration

The mother liquid penetrates through the filtration medium across the inner wall of the basket to complete the primary filtration, which begins as the material enters and ends as the liquid just immerses the inner surface of the solid cake. For the mother liquid containing colloid protein, the mother liquid containing the colloid protein will be removed by means of the skimming device in the course of filtration.

Washing

The solid cake is usually washed after the primary filtration. Add the washing liquid through the feeding pipe or washing pipe, and level of the washing liquid is monitored in the material level detector. Washing is completed once the pre-set washing load is achieved and the solid cake is immersed into the liquid.

Dry spinning

The basket accelerates to the high speed for drying the solid cake, and filtration is completed after the moisture content of the solid cake reaches the required value or the solid cake takes the pre-set drying duration.

Discharging

The solid cake is removed by the scraping device at high speed or that is decelerating, and the removed cake is discharged through the discharge mechanism. The solid phase can be discharged in two modes: discharging chute and scroll conveyor.

Regeneration of filter cloth

Residual solid cake can be found on the inner wall of the basket after the scraper discharges the material, the filtration basket can loosen the solid cake through the high-pressure gas on the back of the basket, and then remove the solid cake by means of the scraper device. In the siphon basket, the back washing liquid can be added into the basket from the high-level-mounted back washing tank through the suction chamber, and then reversely penetrates the residual solid cake so as to make the solid cake suspended and restore its permeability.

Structural Advantages

- Dovetail slot design is adopted for door and base fitting flange to ensure reliable sealing.

- Full-hydraulic locking door and dual-locking protection are designed to ensure structural reliability and easy operation.

- Large bearing capacity and good vibration attenuation effect.

- Anti-slip base plate, without fixing the equipment with bolts.

- Integrated design of floating platform and vibration attenuation system.

- Dynamic load isolated positively, with no need to lay a foundation, easier to be installed.

- Imported damper adopted for the vibration absorber, with special structural design to effectively improve the vibration isolating capacity as well as the equipment running safety and stability.

- Integrated design for the equipment base, which is manufactured as a whole to ensure both aesthetic appearance and production safety.

- Coaxial machining for the front and rear bearings to ensure high coaxial precision.

- Ion plating process employed for the spindle sleeve to resist wear and corrosion, and realize a longer service life.

- Welded as a whole to eliminate stress, with high strength and strong vibration resistance.

- Multiple sealing structures such as lip seal, air-tight seal and labyrinth seal adopted to ensure reliable sealing for transmission.

- Forcible lubricant spraying mode adopted to ensure good lubricating and cooling effect.

- Devices for detecting the temperature, velocity, vibration, etc. are configured for the spindle assembly to realize real-time monitoring of the equipment's operation.

![]()