Screen 2500rpm Thickening Centrifuge 30kW Chemical Substances Separating Centrifuge

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | LLWZ |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | To be negotiated |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 60 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Features: | Automatic Working, Saving Labor | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

|---|---|---|---|

| Centrifugal Type: | Screen Worm Centrifuge | Discharge: | Scroll Discharge |

| Machine Control: | PLC Control | Rotating Speed Control: | Frequency Converter |

| Control System: | PLC Control | Condition: | New |

| Highlight: | 2500rpm Thickening Centrifuge,2500rpm centrifuge machine industrial,Thickening Centrifuge 30kW |

||

Product Description

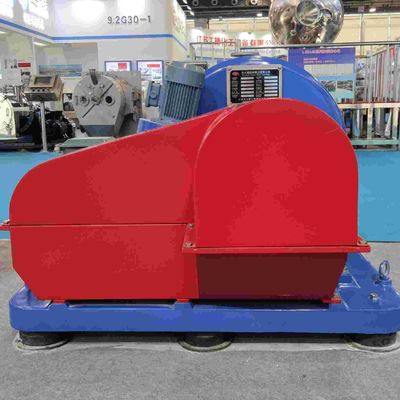

LLWZ450 Continuous Running Screen Chemical Substances Separating Centrifuge

Horizontal screen worm centrifuge has been widely applied in the chemical, food, salt, mining, pharmaceutical and other industries. Based on its separation principle, structural characteristics and relatively specific separation objects, this product is mainly applicable to the separation of materials with relatively large particle sizes and without strict requirements for the integrity of the particles, such as various crystals, fibers, crop shells, and plastic particles.

![]()

Successful Applications

| Adipic acid | Mirabilite | Pyrazole | AH-Salt | Ammonium persulfate | Gypsum | Silver nitrate | Ammonium phosphate |

| Ammonium sulfate | Ion exchange resin | Sodium chloride | Anthracene | Sodium chlorate | Acetylsalicylic acid | Sodium formate | Manganese sulfate |

| Borax | Methyl collulose (MC) | Calcium formate | Sodium nitrate | Sodium perborate | Sodium phosphate | Citric acid | Sodium sulfate |

| Polystyrene | Polystyrene alcohol | Sodium thiosulfate | Potash (potassium carbonate) | Tartaric acid | Crystallized soda | Potassium vanadium | Trisodium phosphate |

| Potassium bicarbonate | Zinc sulfate | Pentaerythritol | Plastic particles | Ammonium thiosulfate | Sodium metaborate | Copper sulfate | Glacial acetic acid |

| Potassium chloride | Potassium pentasulfide | Potassium phosphate | Potassium sulfate | ...... |

Technical Parameters

| Model | Bowl Diameter (mm) | Speed (r/min) | Separation Factor | Capacity(m³/h) | Power of Driving Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LLWZ450 | 450 | 2500 | 1575 | 2-8 | 30 | 1800 | 1800*1400*1250 |

Huada History

The Company successively researched and developed AUT, LGZ, LW, GK and other series of models, and successfully put them into the market.

Jiangsu Huada applied for a patent for its PLD automatic vertical bottom discharge scraper centrifuge with Auxiliary Pulling Bag, obtained the certificate for invention patent and won the National Patent Excellence Award in 2012.

Huada was merged by SCIMEE Sci.& Tech. Co., Ltd. (stock code: 300425) and became a wholly-owned subsidiary of the listed company.

SCIMEE became a holding company of CSCEC and Huada became a state-owned holding company with an annual output value of more than RMB 300 million for three consecutive years.

In September 1993, Zhangjiagang Huada Centrifuge Co., Ltd. was established.

Jiangsu Huada Phase-II Project was completed and put into use, achieving an annual productivity of 1,500 centrifuges.

Jiangsu Huada was changed into Huada as a whole with registered capital changed to RMB 60 million.

With an annual output value of more than RMB 350 million, Huada produced more than 1,600 sets of products annually.

Jiangsu Huada Phase-III Project was officially launched, and the environmental protection equipment workshop was completed, realizing mass production.

Working concepts

Setting goals, highlighting results, being positive and happy and realizing the value of life; learning culture, innovation culture, quality culture, safety culture, performance culture, love culture

Technological Innovation

Technological innovation is the first driving force for development. Gathering a group of engineers and technicians dedicated to developing filtration and separation technologies, Huada has undertaken many national torch plan projects, key new product projects, key scientific and technological projects, etc., and has won various provincial and municipal awards and honors.

After years of continuous innovation and development, it has researched and developed various types of centrifuge products and complete sets of equipment, and has accumulated rich experience in their application in the chemical engineering, pharmaceuticals, energy, food, environmental protection and other industries.

Technological Strength

Currently, Huada has 10 senior engineers, 45 engineers and 83 engineering technicians, a Jiangsu Provincial Engineering and Technology Research Center and an Equipment Technology Research Institute. It does not only have a powerful technology research center, but also has established long-term technical cooperation with domestic research institutes, universities and other institutions and has served as a practice base for many universities.

R&D Ability

It has successfully developed more than 40 series of products such as PLD, LGZ, PGZ, PSD, PSB, PBZ, PQLD, PQFB, PQFD, GK, GKH, GKF, LW, LLW and LLWZ, and more than 200 models, and has R&D ability for a variety of new products and new technologies each year.

Achievements in Scientific Research

It has 62 national patents for invention, and has presided over and participated in the drafting of many national and industrial standards like Three-column and Four-point Suspension Centrifuges, Screen Worm Centrifuges, Explosion-proof Peeler Centrifuges, Peeler Centrifuges and Decanter Centrifuges.

Customers Are More at Ease with Guaranteed Services:

Free technical consultation

Free maintenance within the warranty period

Free equipment software upgrading

Application for free return if the product technology is not applicable

More Assured in Use with Guarantees for Products

Technology

It has focused on the R&D and application of filtration and separation technologies for nearly 30 years, making the products more specialized and advanced.

Quality

It has a professional quality management team and standardized inspection procedures to achieve effective control over the whole process of design, procurement, manufacturing, services, etc., to ensure that each product is acceptable and traceable.

Safe

With experience in separation of more than 2,000 kinds of materials, it can meet the on-site anti-corrosion, explosion-proof, GMP and other requirements of the customers, and realize remote intelligent control and fault diagnosis of equipment.

Efficiency

It has a modern professional management team, an information-based efficient office platform and an automatic production workshop, which uses standard grinding tools for production and has an annual productivity of 1,800 sets to ensure that the products are delivered on time.

Services

It has an efficient professional service team, making services available anywhere.

Cost

It ensures that all customers can have high-tech, high-quality, high-precision, safer products at more favorable prices.

Eco-friendly

It continuously optimizes the product structure design, configuration and plans to meet the environmental protection design requirements, reduce costs and increase benefits for customers.

![]()