Stainless Steel Peeler Discharge 800mm Food Centrifuge Machine PE Lined

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB 19815-2005, GBT19001-2016/ISO9001:2015 |

| Model Number: | GKF1600 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | To be negotiated |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 70 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Certificate1: | GMP Standard |

|---|---|---|---|

| Basket Length (mm): | 800 | Max. Loading Weight (kg): | 930 |

| Centrifugal Type: | Pharmaceutical Centrifuge | Operation Type: | Automatic Bacth Operation |

| MOC: | SS304/316L | Separation Factor: | 808 |

| High Light: | food centrifuge machine PE Lined,930kg continuous centrifugal separator,800mm food centrifuge machine |

||

Product Description

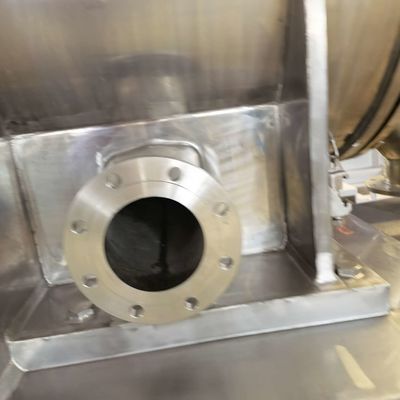

GKF High Sanitation GMP Stainless Steel PE Lined Peeler Discharge Food Centrifuge Machines

With special structural design and system configuration, GKF pharma peeler centrifuge can be used to obtain pharmaceutical products or intermediate products that meet the GMP (FDA, COS, TGA) standards with reasonable consumption, without generating new impurities and pollutants during the operation.

![]()

GKF centrifuge series are new types of products integrated with multiple patents.

Scope of application: particle diameter: 0.05mm~1mm

Solid content: 10%~50%

Cake density: 1~1.5

Characterized by automatic control, batch processing, continuous working, short circulating period, large handling capacity, low moisture and good washing effect, the product is applicable to the solid-liquid separation of toxic, hazardous, inflammable and explosive media of low viscosity and with high requirements for sanitation. It has been widely applied in the pharmaceutical production, food production and other fields.

![]()

Technical Parameters

| Model | ||

| Items | GKF1600 | |

| Basket Diameter (mm) | 1600 | |

| Basket Length (mm) | 800 | |

| Filtering Area | 4 | |

| Basket Volume (L) | 700 | |

| Max. Loading Weight (kg) | 930 | |

| Basket Speed (r/min) | 950 | |

| Separation Factor | 808 | |

| Power of Driving Motor (kW) | 90 | |

| Dimension(L×W×H)(mm) | Machine | 5100*2500*3100 |

| Dimension(L×W×H)(mm) | Installation | 6400*4400*3100 |

| Weight(kg) | 25000 | |

![]()

Main Features

- Action elements like feeding, filtration, washing, dry spinning, discharging and residual cake removal is with automatic electric-hydraulic control.

- Big hinged cover design makes it easy to clean all parts in the basket and the operation zone. Quick-opening hydraulic locking device ensures easy and reliable operation.

- Inverter control realizes stepless speed regulation of the basket. Flexible process time set for feeding, washing, filtration, discharging and residual solid cake removal and purging.

- Liquid-damping vibration isolators without floating platform ensure stable operation of the centrifuge.

- Dual shaft seal structure design protects the clean room from contamination of lubrication oil and other pollutants. All seals are made of the fluorous rubber and silicon rubber.

- Multiple safety protection system: includes rotation speed monitoring, over-vibration protection, cover opening protection, motor overload and overheat protection, electric-hydraulic interlocking protection for cover locking device, scraper limit protection, main shaft temperature rise protection, lubrication oil failure protection and other devices.

- With high-quality stainless steel material of construction for the centrifuge and high-grade mirror finishing surface treatment, which meets the requirements for anti-corrosion and sanitation.

Customers Are More at Ease with Guaranteed Services:

Free technical consultation

Free maintenance within the warranty period

Free equipment software upgrading

Application for free return if the product technology is not applicable

More Assured in Use with Guarantees for Products

Technology

It has focused on the R&D and application of filtration and separation technologies for nearly 30 years, making the products more specialized and advanced.

Quality

It has a professional quality management team and standardized inspection procedures to achieve effective control over the whole process of design, procurement, manufacturing, services, etc., to ensure that each product is acceptable and traceable.

Safe

With experience in separation of more than 2,000 kinds of materials, it can meet the on-site anti-corrosion, explosion-proof, GMP and other requirements of the customers, and realize remote intelligent control and fault diagnosis of equipment.

Efficiency

It has a modern professional management team, an information-based efficient office platform and an automatic production workshop, which uses standard grinding tools for production and has an annual productivity of 1,800 sets to ensure that the products are delivered on time.

Services

It has an efficient professional service team, making services available anywhere.

Cost

It ensures that all customers can have high-tech, high-quality, high-precision, safer products at more favorable prices.

Eco-friendly

It continuously optimizes the product structure design, configuration and plans to meet the environmental protection design requirements, reduce costs and increase benefits for customers.