1500rpm Decanter Centrifuges For Waste Oil Stream Recycling

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | LW |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD20000-180000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 70 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Centrifugal Type: | Decanter Centrifuge |

|---|---|---|---|

| Discharge: | Scroll Discharge | Machine Control: | PLC Control |

| MOC: | Stainless Steel | Certificate: | ISO9001 |

| Operate: | Automatic Continuous Operation | Bowl Speed (r/min): | 1500-4800 |

| High Light: | 1500rpm Decanter Centrifuges,1500rpm continuous centrifugal separator,Decanter Centrifuges 132kW |

||

Product Description

LW High-Quality High-Precision Safer Products Decanter Centrifuge For Waste Oil Stream Recycling

Description

LW series products are decanter centrifuges that can work continuously and are mainly used for solid-liquid separation, dehydration, fractionation, clarification, and concentration of materials. Based on different phase densities, it separates the solid phases and liquid phases under the action of the centrifugal force generated by the high-speed revolution of the Bowl. The solid phases are conveyed to the conical end of the Bowl through a spiral and then discharged, and the liquid phases are discharged out from the overflow port at the big end of the Bowl. Characterized by simple design, high efficiency and scientific configuration, this product has been widely applied to chemical, pharmaceutical, environmental protection, food, mining, energy and other industries.

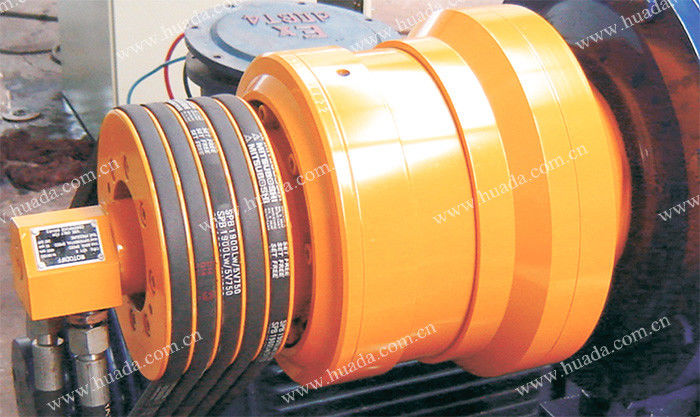

Hydraulic scroll driving system

Operating principle

The hydraulic conveyor gearbox is connected with the bowl of the decanter centrifuge, both of them rotates in high speed. The spline shaft on the gearbox rotor is connected with the conveyor, and rotates in different speed driven by the high pressure oil, that's we call the differential speed. The conveyor gearbox is connected with the hydraulic pump by flexible hose, so there is no need of gearbox between the bowl and conveyor. Conveyor torque gives pressure to the hydraulic system. With the action of such pressure, the different speed can by adjusted by adjusting the oil supply and flow rate.

![]()

Technical Parameters

| Model | Bowl Diameter (mm) | L/D | Bowl Speed (r/min) | Separation Factor | Power of Driving Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LW220*880 | 200 | 4 | 4800 | 2840 | 11 | 1000 | 2660*740*780 |

| LW300*1290 | 300 | 4.3 | 4400 | 3250 | 15 | 1500 | 3250*960*1000 |

| LW355*1460 | 350 | 4.17 | 4000 | 3130 | 22-30 | 2200 | 3550*1010*1030 |

| LW450*1800 | 450 | 4 | 2800-3200 | 1575-2580 | 30-37 | 3500 | 4150*1090*1250 |

| LW450*2050 | 450 | 4.5 | 3200-3600 | 2580-3265 | 30-37 | 4000 | 4350*1090*1250 |

| LW530*2120 | 530 | 4 | 2800-3200 | 2330-3040 | 45-55 | 5300 | 4850*1230*1450 |

| LW530*2650 | 530 | 5 | 2500 | 1850 | 55 | 6000 | 5400*1230*1450 |

| LW650*2800 | 650 | 4.3 | 2500 | 2270 | 90 | 9600 | 5400*1750*1600 |

| LW720*2880 | 720 | 4 | 2000 | 1610 | 110 | 11000 | 5300*2050*1750 |

| LW850*3200 | 720 | 3.76 | 2000 | 1900 | 160 | 16000 | 6750*2280*1900 |

| LW1000*3000 | 1000 | 3 | 1500 | 1260 | 132 | 16000 | 5200*2500*2000 |