Continuous Oilfield Drilling Solid Bowl Decanter Centrifuges Explosion Proof

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | LWXF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD50000-250000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 70 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Centrifugal Type: | Decanter Centrifuge |

|---|---|---|---|

| Discharge: | Scroll Discharge | Machine Control: | PLC Control |

| MOC: | Stainless Steel | Certificate: | ISO9001 |

| Operate: | Automatic Continuous Operation | Bearing: | NSK Or SKF |

| Application: | Explosion-proof Decanter Centrifuge | ||

| High Light: | Oilfield Drilling Decanter Centrifuges,Continuous centrifugal separator oil,Decanter Centrifuges Explosion Proof |

||

Product Description

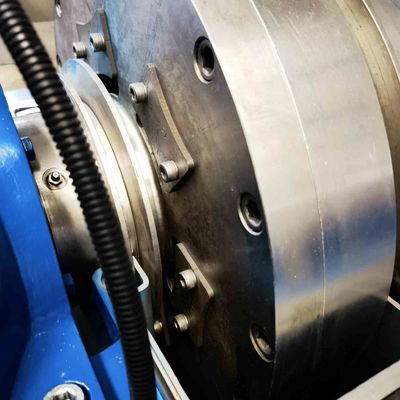

LWF Continuous Oilfield Drilling Explosion-Proof Solid Bowl Decanter Separation Equipment

LWF Explosion-proof Decanter Centrifuge System

Attention: due to the principle of sealing, some of the injected inert gas will leak into the surrounding environment. Therefore, it is required to make sure that there should be enough oxygen in the operation environment. It is necessary to install an additional environment monitoring system (such as gas detector) so as to ensure personnel safety.

![]()

Technical Parameters

| Model | Bowl Diameter (mm) | L/D | Bowl Speed (r/min) | Separation Factor | Power of Driving Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LWFX355*1460 | 350 | 4.17 | 4000 | 3130 | 22-30 | 2200 | 3450*1010*1030 |

| LWFX420*1680 | 420 | 4 | 3600 | 3050 | 30-37 | 4000 | 3500*1450*1300 |

| LWFX530*2120 | 530 | 4 | 3200 | 3040 | 45-55 | 5500 | 4100*1600*1450 |

| LWFX720*2880 | 720 | 4 | 2000 | 1610 | 110 | 11000 | 5300*2050*1750 |

![]()

Wide-ranging performance

Decanter centrifuge provide exceptional performance whenseparating solids from liquids, andmake it possible to do so continuously,efficiently and controllably.

Decanter centrifuges are designed to handle a wide range ofsolid particles with diameters from 5mm to a few microns.

Decanter centrifuge can also handle slurries with a solid content from as low as 0.1% w/w to more than 65% w/w.

![]()

Working principle

The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach.

The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl.

There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.

The light liquid phase is discharged into the casing through radial holes in the large end hub. The heavy liquid phase is discharged through axial holes in the large end hub. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The liquid level is controlled by plate dams. In order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub.

The heavy liquid phase has to pass under the separating plate before being discharged into the casing. The liquid radius for the heavy liquid phase is controlled by plate dams. The solids are discharged in the normal way.

![]()