3000rpm Worm Screen Centrifuge Applied To Tin Sulphate Separation

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 |

| Model Number: | LLW |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD20000-100000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 80 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Centrifugal Type: | Screen Worm Centrifuge |

|---|---|---|---|

| Discharge: | Scroll Discharge | Machine Control: | PLC Control |

| MOC: | Stainless Steel | Certificate: | ISO9001 |

| Operate: | Automatic Continuous Operation | Bearing: | NSK |

| Highlight: | 3000rpm Worm Screen Centrifuge,3000rpm continuous horizontal centrifuge,Worm Screen Centrifuge ISO9001 |

||

Product Description

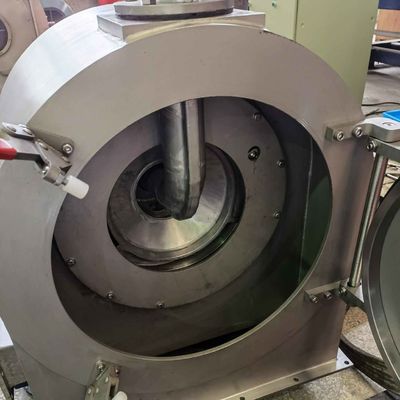

LLW 3000r/Min Worm Screen Centrifuge Applied To Tin Sulphate Separation

LLW Worm Screen Continuous Industrial Centrifuge

LLW centrifuge is a horizontal spiral discharge filtering centrifuge. It has the advantages of smooth rotation, good washing results, large treatment capacity and high production efficiency. It can feed, wash, dewater and discharge automatically and continuously during the rotation at full speed. It’s efficient separating equipment of separating solid from liquid. It is widely used in chemical, pharmaceutical, food ,metallurgy, mine etc .It is suitable for separation of suspension materials with 10-80% density and crystal or lineal grain with diameter between 0.13mm and 5mm (0.2mm is better), such as citrate, salt, fruit juice, sulphuric ammonium and urea etc.

The machine design corresponds to GMP requirements.

It can run continuously and deal with materials greatly.

Several various bowls and spiral roll canisters make wide use.

Reasonable power setting and low consumption.

The parts touching separated materials are made of Austenite stainless

Successful Applications

| Adipic acid | Mirabilite | Pyrazole | AH-Salt | Ammonium persulfate | Gypsum | Silver nitrate | Ammonium phosphate |

| Ammonium sulfate | Ion exchange resin | Sodium chloride | Anthracene | Sodium chlorate | Acetylsalicylic acid | Sodium formate | Manganese sulfate |

| Borax | Methyl collulose (MC) | Calcium formate | Sodium nitrate | Sodium perborate | Sodium phosphate | Citric acid | Sodium sulfate |

| Polystyrene | Polystyrene alcohol | Sodium thiosulfate | Potash (potassium carbonate) | Tartaric acid | Crystallized soda | Potassium vanadium | Trisodium phosphate |

| Potassium bicarbonate | Zinc sulfate | Pentaerythritol | Plastic particles | Ammonium thiosulfate | Sodium metaborate | Copper sulfate | Glacial acetic acid |

| Potassium chloride | Potassium pentasulfide | Potassium phosphate | Potassium sulfate | ...... |

LLW Screen Worm Centrifuge (Standard Type)

![]()

Technical Parameters

| Model | Bowl Diameter (mm) | Speed (r/min) | Separation Factor | Capacity(m³/h) | Power of Driving Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LLW320 | 320 | 2630 | 1240 | 0.5-3 | 7.5 | 700 | 1050*1350*1000 |

| LLW350 | 350 | 3000 | 1765 | 1-5 | 11 | 1200 | 1520*1380*1190 |

| LLW450 | 450 | 2500 | 1575 | 2-8 | 22 | 1700 | 1570*1240*1200 |

| LLW530 | 530 | 2000 | 1190 | 3-10 | 30 | 2500 | 1680*1390*1340 |

| LLW630 | 630 | 1800 | 1140 | 5-15 | 37 | 3500 | 2100*1430*1530 |

| LLW800 | 800 | 1500 | 1000 | 8-20 | 55 | 4500 | 2500*2200*1800 |

| LLW1000 | 1000 | 900 | 450 | 10-30 | 75 | 6200 | 3200*2200*2300 |

LLW Screen Worm Centrifuge (Mechanical Gearbox Type)

![]()

Technical Parameters

| Model | Bowl Diameter (mm) | Speed (r/min) | Separation Factor | Capacity(m³/h) | Power of Driving Motor (kW) | Power of Hydraulic Station Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LLW530Y | 530 | 2000 | 1190 | 3-10 | 30 | 11-18.5 | 2500 | 1680*1390*1340 |

| LLW630Y | 630 | 1800 | 1140 | 5-15 | 37 | 15-30 | 3500 | 2100*1430*1530 |

LLW Screen Worm Centrifuge (Screw Feeding Type)

![]()

Technical Parameters

| Model | Bowl Diameter (mm) | Speed (r/min) | Separation Factor | Capacity(m³/h) | Power of Driving Motor (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LLW350LX | 350 | 2500 | 1765 | 1-5 | 11 | 1400 | 2300*1180*1000 |

| LLW450LX | 450 | 2500 | 1575 | 2-8 | 22 | 2000 | 2360*1210*1040 |

| LLW530LX | 530 | 2000 | 1190 | 3-10 | 30 | 2800 | 2650*1350*1230 |

| LLW630LX | 630 | 1800 | 1140 | 5-15 | 37 | 4200 | 3050*1580*1400 |