SS316L Top Discharge Centrifuge 1500rpm Stainless Steel Sugar Centrifuges

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 01418P10003R2M |

| Model Number: | PSD |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD12000-65000/set |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 65 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Basket Diameter(mm): | 800-1800 | Effective Basket Height(mm): | 450-750 |

|---|---|---|---|

| Discharge: | Bag Lifting Top Discharge | Max. Capacity(kg): | 150-1100 |

| MOC: | Stainless Steel | Motor Power(kw): | 7.5-37 |

| Operate: | Manual Batch Operating | Weight(kg): | 1500-10000 |

| High Light: | SS316L Top Discharge Centrifuge,stainless steel sugar centrifuges,Top Discharge Centrifuge 1500rpm |

||

Product Description

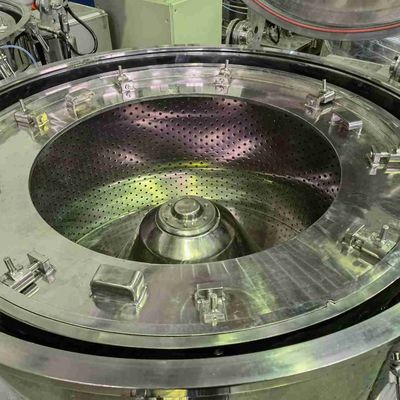

PSD Top Dishcharge Stainless Steel 316L Bag Lifting Cost-Effective Stainless Steel Sugar Centrifuges

Product Overview

Aided mechanical discharge is adopted for the PSD centrifuge. Combining high efficiency of the automatic peeler centrifuge and wide application scope of the top discharge centrifuge, this product is advanced in structural design, small in floor covering area, low in failure rate and high in cost performance.

![]()

Technical Parameters

| Items | Models | ||||||

| PSD800 | PSD1000 | PSD1200 | PSD1250 | PSD1500 | PSD1600 | PSD1800 | |

| Basket Diameter(mm) | 800 | 1000 | 1200 | 1250 | 1500 | 1600 | 1800 |

| Effective Basket Height(mm) | 450 | 520 | 550 | 630 | 680 | 800 | 750 |

| Basket Volume(L) | 120 | 200 | 270 | 400 | 555 | 800 | 910 |

| Max. Capacity(kg) | 150 | 250 | 340 | 500 | 700 | 1000 | 1100 |

| Max. Speed(r/min) | 1500 | 1200/1400 | 1100 | 1000/1200 | 850 | 850 | 780 |

| Max. Separation Factor | 1007 | 805/1096 | 812 | 700/1007 | 606 | 647 | 612 |

| Motor Power(kw) | 7.5 | 11/15 | 15 | 18.5/22 | 30 | 37 | 37 |

| Dimension(mm) | 1730*1200*1320 | 1970*1400*1500 | 2300*1550*1500 | 2550*1800*1780 | 2750*2200*1750 | 3200*2400*2150 | 3300*2500*2150 |

| Weight(kg) | 1500 | 2500/2700 | 3200 | 4000/5000 | 6500 | 8500 | 10000 |

![]()

Scope of Application

This product can be used for the solid-liquid separation of suspensions containing solid particles, as well as for the solid-liquid separation of fibrous materials, such as gypsum, copper sulfate, potassium chloride, borax, dyes, pesticides, salt, monosodium glutamate, food additives, starch, sugar, chemical seasoners, antibiotics, vitamins, copper, zinc, aluminum and other minerals, metal refining, sludge treatment, and sewage treatment has been widely applied in the pharmaceutical, chemical, food, environmental protection, energy and other industries.

![]()

Product Features

1,Inverter start-up, smooth starting, adjustable relative centrifugal force.

2,Discharge cake by lifting out filter cloth is highly efficient with low labour intensity; No damage to the particles; Wide range of applications.

3,Well-designed structure and polished surface leaves no residual heel. With big hinged cover, it is easy to clean the gap between the case and the basket.

4,Overall welding structure between the base and the case ensures high carrying strength.

5,Platform base design lowers the center of gravity and requires minimum installation space. The platform base can be used for operation platform.

6,Liquid-damping vibration isolators, simplify the routine maintenance.

7,Big hinged cover, feed pipe, wash pipe, observation glass and light.

8,Automatic CIP system cleans the internal surface of the case, the basket and liquid slot to meet the clean requirement in accordance with GMP standards.

9,Tightness structure with silicone rubber or fluoroelastomers seals. Nitrogen protection system(optional)is for anti-explosion applied to poisonous, flammable and explosive environment.

10,Equipped with hydraulic suspension arms with external fully-stainless steel surface (optional), which is easy for discharging and complies with the sanitation requirements.

![]()