Bag Lifting Top Discharge Centrifuge Spent Grains Separating Stainless Steel 904L

Product Details:

| Place of Origin: | CHINA, JIANGSU |

| Brand Name: | HUADA |

| Certification: | GB/T19001-2016/ISO9001:2015 01418P10003R2M |

| Model Number: | PSD800-1800 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | To be negotiated |

| Packaging Details: | Standard with wooden pallet and poly film wrapping |

| Delivery Time: | 60 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Centrifugal Type: | Basket Centrifuge |

|---|---|---|---|

| Effective Basket Height(mm): | 630 | Max. Separation Factor: | 700/1007 |

| MOC: | Stainless Steel | Motor Power(kw): | 18.5/22 |

| Operate: | Manual Batch Operating | Basket Diameter(mm): | 1250 |

| High Light: | Top Discharge Centrifuge Stainless Steel 904L,22kW stainless steel centrifuge,Bag Lifting Top Discharge Centrifuge |

||

Product Description

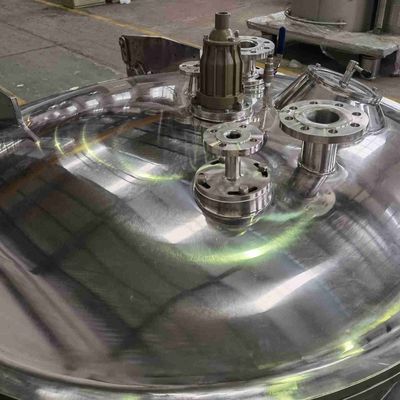

PSD Small Batch Type Bag-Lifting Top Discharge Spent Grains Separating Stainless Steel 904L Centrifuge

Main applications

Apply to separating material with granulate particle shape, but also fibers, like plasters, bluestone, potassium chloride, borax, dyestuffs, pesticides, salts, gourmet powders, foodstuff additives, chemical flavors, antibiotics, vitamins, the metals like copper, zinc and aluminum, metal products, sludge, etc.

![]()

Technical Parameters

| Items | Models | ||||||

| PSD800 | PSD1000 | PSD1200 | PSD1250 | PSD1500 | PSD1600 | PSD1800 | |

| Basket Diameter(mm) | 800 | 1000 | 1200 | 1250 | 1500 | 1600 | 1800 |

| Effective Basket Height(mm) | 450 | 520 | 550 | 630 | 680 | 800 | 750 |

| Basket Volume(L) | 120 | 200 | 270 | 400 | 555 | 800 | 910 |

| Max. Capacity(kg) | 150 | 250 | 340 | 500 | 700 | 1000 | 1100 |

| Max. Speed(r/min) | 1500 | 1200/1400 | 1100 | 1000/1200 | 850 | 850 | 780 |

| Max. Separation Factor | 1007 | 805/1096 | 812 | 700/1007 | 606 | 647 | 612 |

| Motor Power(kw) | 7.5 | 11/15 | 15 | 18.5/22 | 30 | 37 | 37 |

| Dimension(mm) | 1730*1200*1320 | 1970*1400*1500 | 2300*1550*1500 | 2550*1800*1780 | 2750*2200*1750 | 3200*2400*2150 | 3300*2500*2150 |

| Weight(kg) | 1500 | 2500/2700 | 3200 | 4000/5000 | 6500 | 8500 | 10000 |

Working Principle

Under the action of centrifugal force, the materials reach the basket wall, where the liquid phase passes through the filtering medium covered on the basket wall and then flows through the pores on the wall to the inner wall of the enclosure, then drops off to the bottom tray and is discharged out via the liquid discharge port.

While the solid matters are retained inside the basket and fully washed to complete the solid-liquid separation. After the equipment is shutdown, open the flippable cover, remove the filter bag with special lifting appliances, transfer it to the unloading area for discharging.

After that, install the basket lip and filter bag back, lock the basket lip, close the flippable cover and lock it, and at this time, the next circulation can be started.

![]()

![]()

Product Features

- Inverter start-up, smooth starting, adjustable relative centrifugal force.

- Discharge cake by lifting out filter cloth is highly efficient with low labour intensity; No damage to the particles; Wide range of applications.

- Well-designed structure and polished surface leaves no residual heel. With big hinged cover, it is easy to clean the gap between the case and the basket.

![]()

SERVICE WARRANTY

Huada has Long tradition customer service, we always try our best.

An effective service management organization ensures professional and flexible management of any affairs.

Huada has a long tradition of customer service and we always do our best to provide assistance.

An effective service management organization can ensure professional and flexible handling of product application business.

Presale consulting - sales staff and sales engineers provide relevant technical advice specific to demands proposed by customers. Technical experts in application can provide technical support where necessary.

Type selection - centrifuge type selection is crucial and decides separation process feasibility, safety, product quality, yield, operation cost, etc. also, it a crucial impact on Infrastructure projects, equipment investment and environmental protection, etc.

For particular separation process requirements, we must totally understand physical and chemical properties of the material. Under the premise of meeting anti-corrosion and anti-explosion requirements (i.e. safety requirements). we can realize filtration and separation requirements and at the same time fully consider the automation, running cost and other factors . Our experts in application technology can put forward the corresponding proposal for specific operating conditions and effectively communicate with your process/ equipment, personnel to ensure reasonable, advanced and economical type selection

Laboratory test - Making laboratory analysis on separation characteristics of the material to provide the basis for type.